Odyssey Air & Nitrogen Boosters

Quincy Compressor is pleased to announce that in January 2024, we acquired the assets of Hycomp, Inc. The exciting news offers tremendous opportunities for current Hycomp and future Quincy Compressor customers. This acquisition brings a wealth of expertise in air and nitrogen boosters, aftermarket parts, and services, allowing us to expand our capabilities and ensure that your existing and new products receive top-notch maintenance and support.

We understand the importance of reliability and longevity when it comes to your investments, and this acquisition indicates our dedication to delivering excellence at every touchpoint of your customer journey.

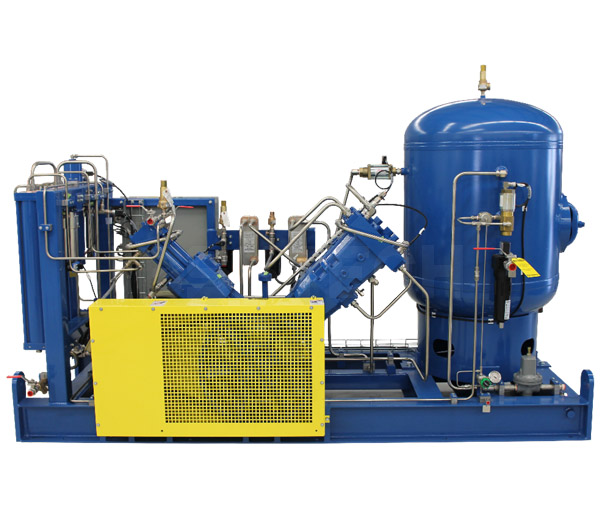

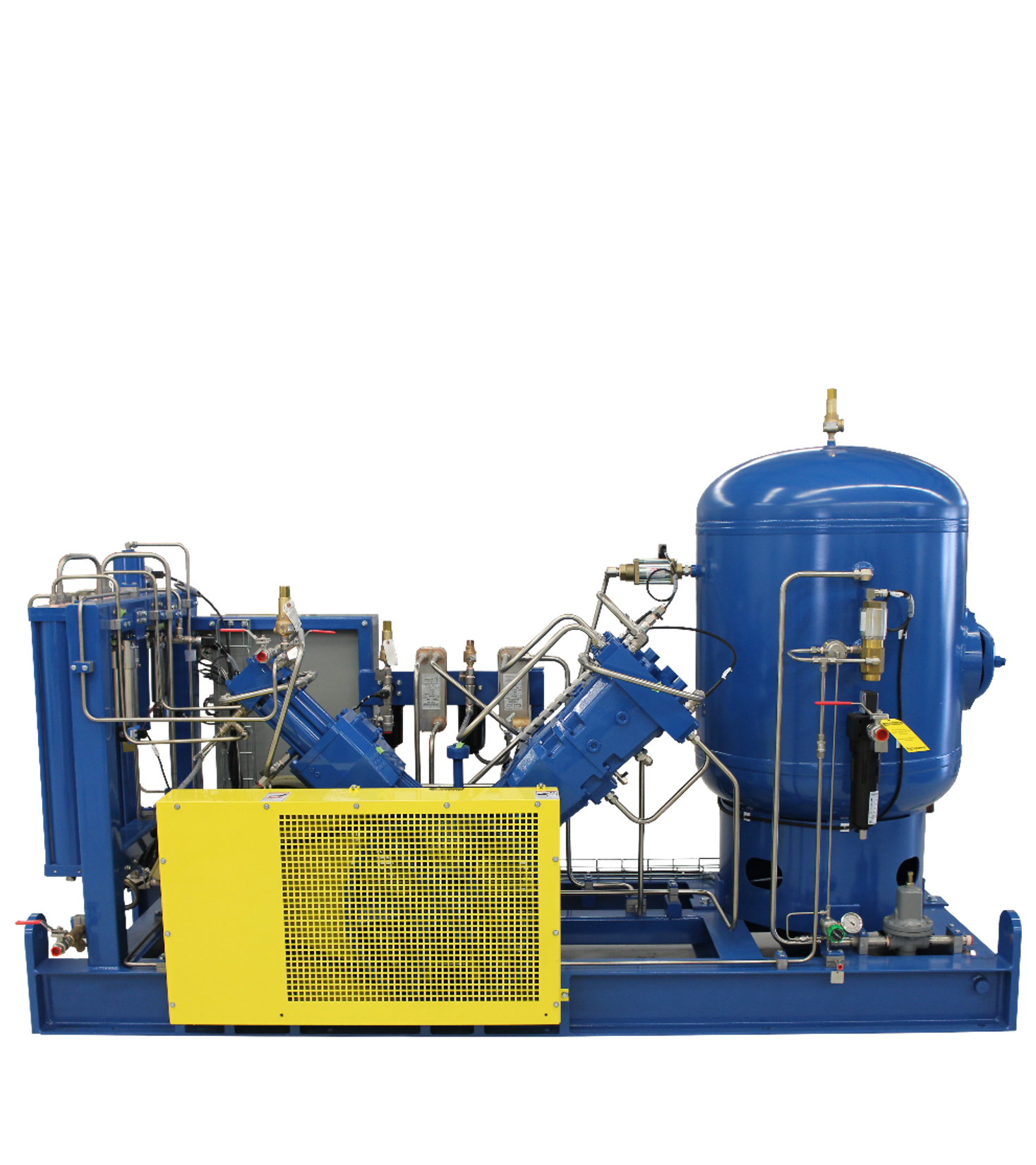

Crafted with precision in the USA, The QDS Odyssey oil-free high-pressure reciprocating boosters are designed to meet the demands of the most rigorous applications. Boasting standard capabilities of up to 600 PSIG and 500 SCFM for both Air and Nitrogen, these boosters are engineered to deliver exceptional performance consistently.

Trust Quincy Compressor’s Odyssey line of Oil-Free Air and Nitrogen boosters for your critical project needs. Designed to prevent contamination and losses of the gas stream, these units provide worry free operation and a 20+ year life expectancy.

CUSTOM SOLUTIONS

If your application doesn’t fit within the published QDS Odyssey lineup, don’t worry, we have boosters capable of delivering a range of pressures, flows, and gasses (beyond Air and Nitrogen), and can design a package specifically to fit your needs.

We take an active role in the application and design of every installation of our boosters to ensure success and begin by acknowledging that every application, and therefore every customer, has unique requirements. With this open mindset, we investigate the details of the application and work out potential problems before they occur. Armed with knowledge and experience we can accurately recommend a tailored booster system to solve your challenge.

Variety of models available capable of 1500psig and limited models up to 3000psig.

Some gases include: Argon, Biogas Methane, Carbon Dioxide, Carbon Monoxide, Ethane, Heliox, Helium, Krypton, LPG, Natural Gas, Neon, Xenon

As the combinations of inlet pressure, discharge pressure, required flow and gas type are nearly limitless, we encourage you to contact us for assistance in sizing the proper gas compressor for your application. Contact our team of experts to help create a custom solution for you.

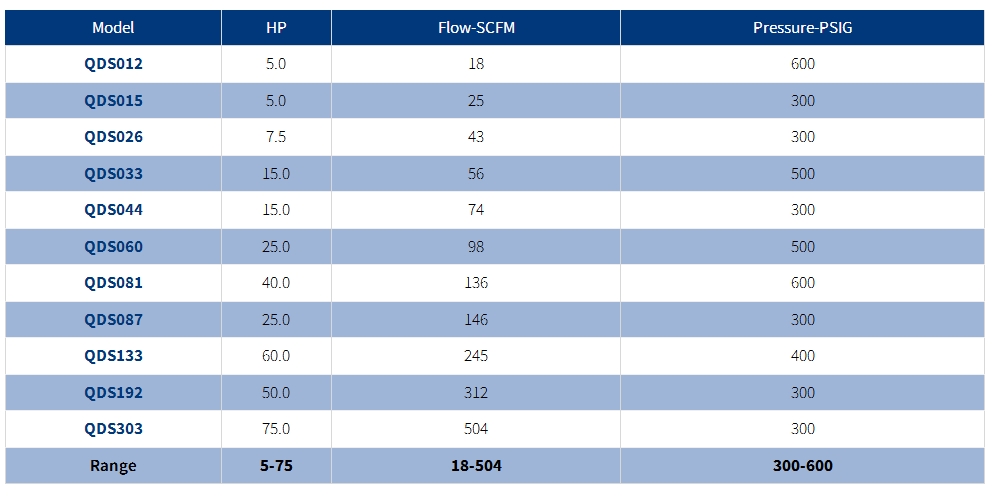

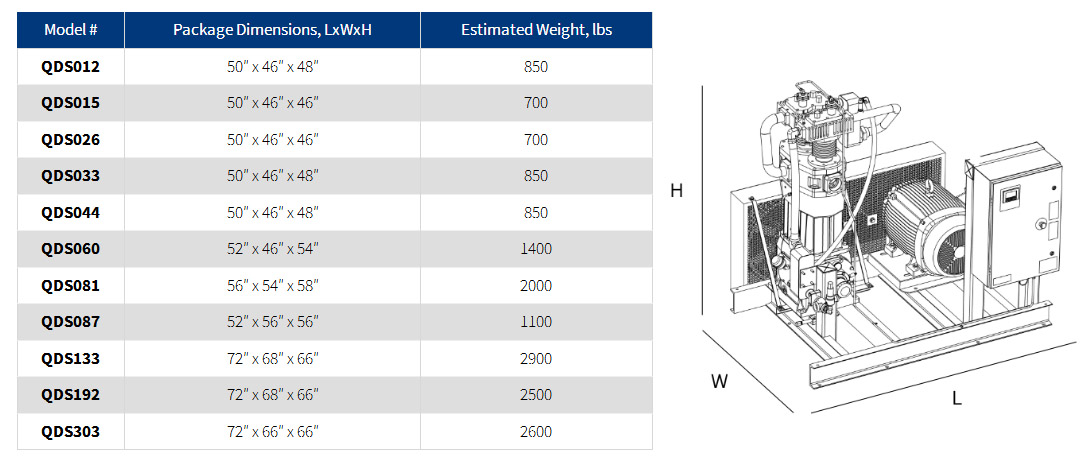

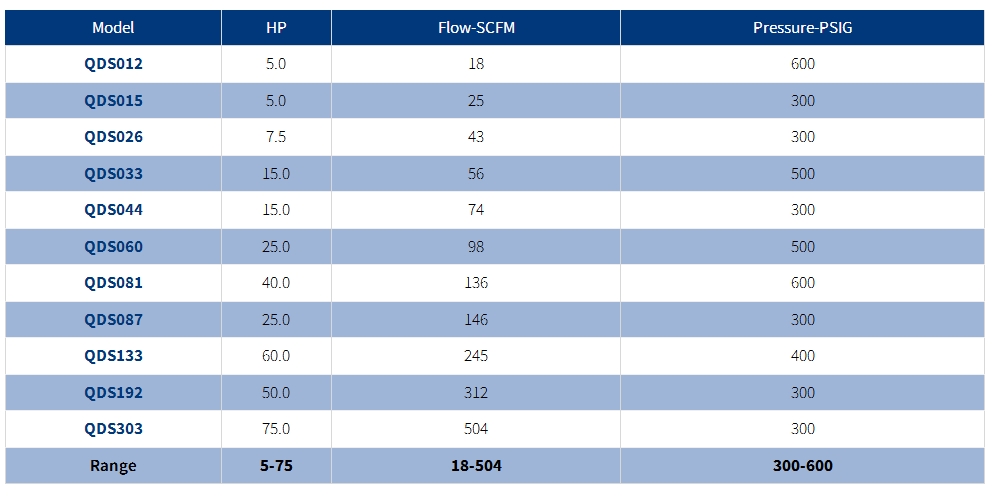

SINGLE STAGE

Generally used for boosting 1.3 to 4 times existing pressure

5 to 75 HP

11 to 504 SCFM

Up to 400 PSIG

Air cooled (Water cooled available upon request)

TWO STAGE

Generally used for boosting 3 to 10 times existing pressure

5 to 60 HP

8 to 245 SCFM

Up to 600 PSIG

Air cooled (Water cooled available upon request)

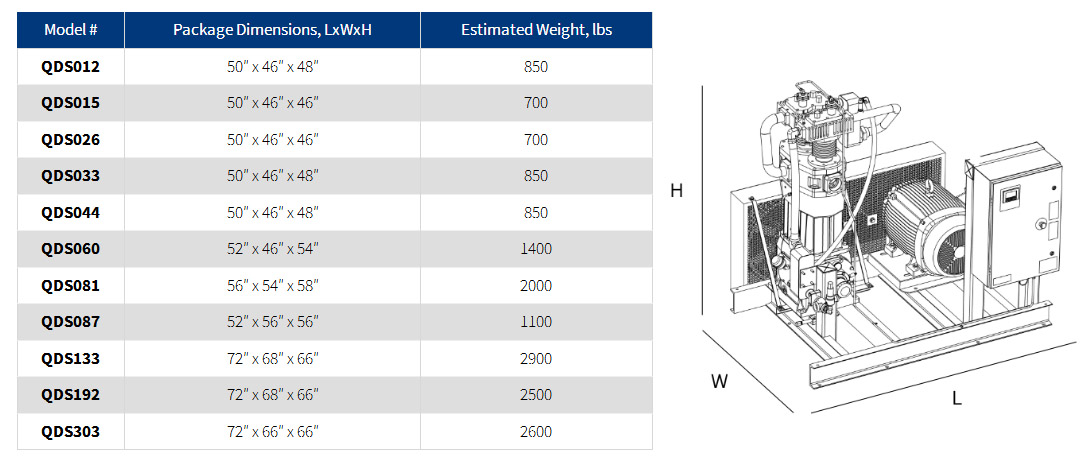

Odyssey Standard Product Range

The Compressor So Reliable You’ll Forget It’s There.

Performance Under Pressure

Standard oil-free compressed air systems in industrial facilities are typically designed for pressures of 80 to 130 psig. When higher pressures are required it is very cost effective to use a portion of your plant air and apply an oil-free air booster to obtain the desired pressure.

Other methods of acquiring higher pressure air such as stand-alone air compressors, air amplifiers and increasing the pressure of the entire plant are more costly and less efficient.

Odyssey Markets and Applications

Electronics — Fiber Optics, N2 Blanketing, Plastics Extruding. Chemical — Breathing Air, Hydrogenator, Liquid Transfer.

Energy, Oil & Gas — Purge Air, Instrument Air, Liquid Transfer. Environmental — Purge Air.

Fire Protection — Suppression Accumulator Bottles, Filling Extinguishers.

Food Production — Fermentation Air.

Heating, Cooling, Refrigeration — Pressure Testing Coils. Institutional — Lab Instrument Air.

Medical Device Mfr — Bead Blasting, Contact Lense Process, Syringe Process, Pressure Testing.

Mining, Minerals — Filter Press. Municipal WWT — Instrument Air.

Plastics/Rubber — Autoclave (lnerting), High Pressure Forming,Vinyl Mfg.

Semiconductor — High Pressure Tools, Specialty Processes (silicon wafer, diode mfg).

Application Spotlight

Laser Cutting Nitrogen Booster

Nitrogen Pressure Boosting

The two main factors when using nitrogen as an assist gas for laser cutting are: purity & high pressure. Purity: Laser cutting machines require high purity nitrogen to provide a precise and clean cut. Low Purity nitrogen could cause oxidizing of the metal and burrs. Quincy Compressor oil-free nitrogen boosters ensure that your nitrogen remains pure as no oil is allowed to enter compression.

High pressure: The nitrogen must be supplied at high pressures, on average 200-450 psig to create clean and precise cuts. Quincy Compressor nitrogen boosters are engineered to provide the pressure your laser cutting application requires.

Available Options

Special Sealing Systems

High Temp Cooling Fan

Modbus TCP/IP Communications

Multiple Unit Lead/Lag & Alternate Controls

NEMA 4X Control Panel Enclosure

Cold Weather Package

Voltage – 200, 208, 230, 400, 575

Moisture Separators

Closed Loop Cooling Skid

Remote Monitoring/Controlling

Stainless Steel Control Panel Enclosure

Odyssey QDSi Easy Install Package

Buffer, Discharge Tank, Filtration and Flow Management System.

Bulletproof Installation

The Odyssey QDSi Easy-Install add-on package greatly reduces the potential for installation errors and incorrect component selection by providing the user with everything needed to ensure a successful turnkey installation. Provided is the plumbing and wiring to connect the suction and discharge to an existing Quincy Compressor booster. Inclusion of Quincy Compressor recommended components, pre-assembled at our facility, ensures a bulletproof installation solution at a lower cost.

Reduced Maintenance Costs

The QDSi Easy-Install package provides protection of equipment with Quincy Compressor specified filters. Inclusion of an inlet filter provides an extra barrier between supplied air/nitrogen and the Quincy Compressor booster. Limiting the amount of debris entering the booster reduces wear and tear on internal components and results in lowered maintenance costs.

Extended Booster Life

The innovative recycle line featured in the QDSi Easy-Install is used to recirculate excess compressed air/nitrogen back through the booster. This results in fewer load/unload cycles, which extends the life of the booster.

Reduces Space Requirements

Recirculation of excess gas also eliminates the need for large and expensive storage vessels, giving the user a better value on the space used in their facility.

Made in the USA

Every system we build is manufactured at our plant in Utah. Replacement parts are stocked on our shelves and available for next day delivery.